CASE STUDY: Harvey - the capsicum-picking robot

Case Studies

Boeing Australia – Where humans and automation work together

Since the 2008 establishment of Boeing’s advanced research and development unit …

IR4 – Mass communication via robotic automation

IR4 is an early revenue technology company that is setting global benchmarks in …

Kalmar – AutoStrad Terminal Solution

Within the next 10-15 years many of the major stevedores will automate and the …

Wide area surveillance of the oceans requires a diversity of solutions …

Rio Tinto’s fleet of autonomous haul trucks have moved more than 1 billion tonnes of …

Share this story

The horticulture industry in Australia has a gross value of more than $AU8 billion dollars per annum. Australia produces more than 36,000 tonnes of capsicum per year, worth approximately $AU92 million, mostly grown in North Queensland [DAF14].

The Queensland Government supported QUT to develop a new agricultural robot prototype designed to harvest capsicums – nicknamed ‘Harvey’. Harvey was developed as part of the Queensland Department of Agriculture and Fisheries (DAF) three-year strategic investment in farm robotics [SIF17]. The SIFR team, led by Professor Tristan Perez, determined the major challenges associated with robotic harvesting were around image processing (green fruit on green background, and heavy ambient occlusion), and manipulation due to the unstructured environment of the crop. The team developed an algorithm to detect approximately 70 per cent of in-field capsicum that improves on state-of-the-art vision systems and is comparable with detection by humans.

Harvey’s robotic arm has a camera and a unique cutting tool attached to it. Using data from the camera, the robot detects the fruit and cutting location and plans and controls the robotic arm and harvesting tool to detach the fruit from the plant. Field trials within a real protected cropping system demonstrated a success rate of 60% for harvesting capsicum with an average picking rate of 20 seconds [LE17]. The combination of state-of-the-art robotic-vision software and novel crop-manipulation tools enable successful harvesting of the crop. This advancement promises significant benefits for horticulture growers, who export more than $AU2 billion in products every year.

Trending Article

Working with robotics technology to improve safety, reliability and efficiency in high-risk and remote environments

Woodside is an Australian oil and gas company with a global presence, recognised for its world-class capabilities – as an explorer, a developer, a producer and a supplier of energy…

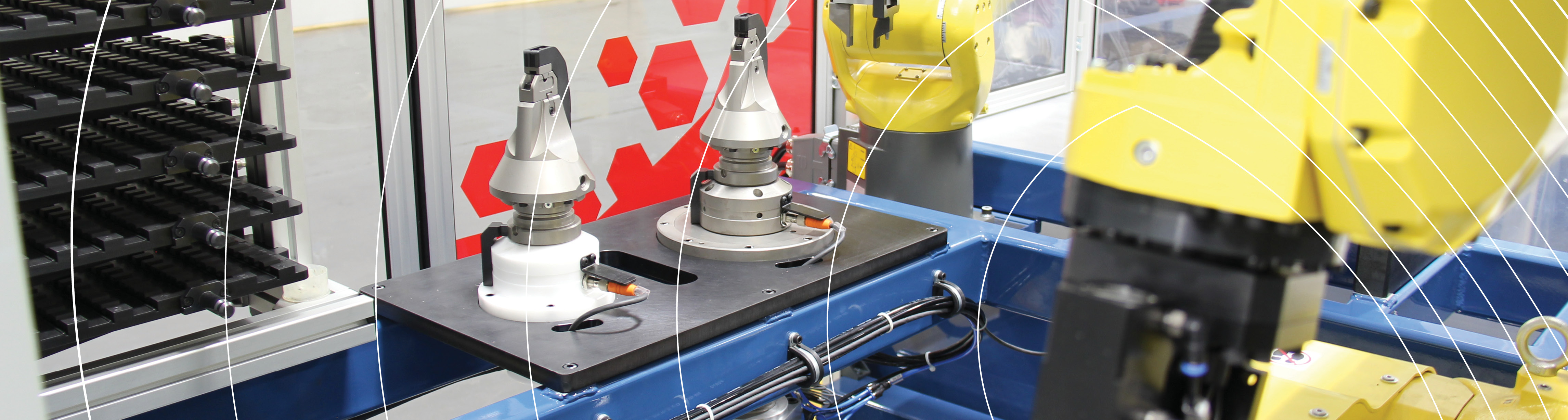

ANCA – Australia’s largest user of industrial robots

ANCA is an Australian company, founded in Melbourne in 1974, now with offices...

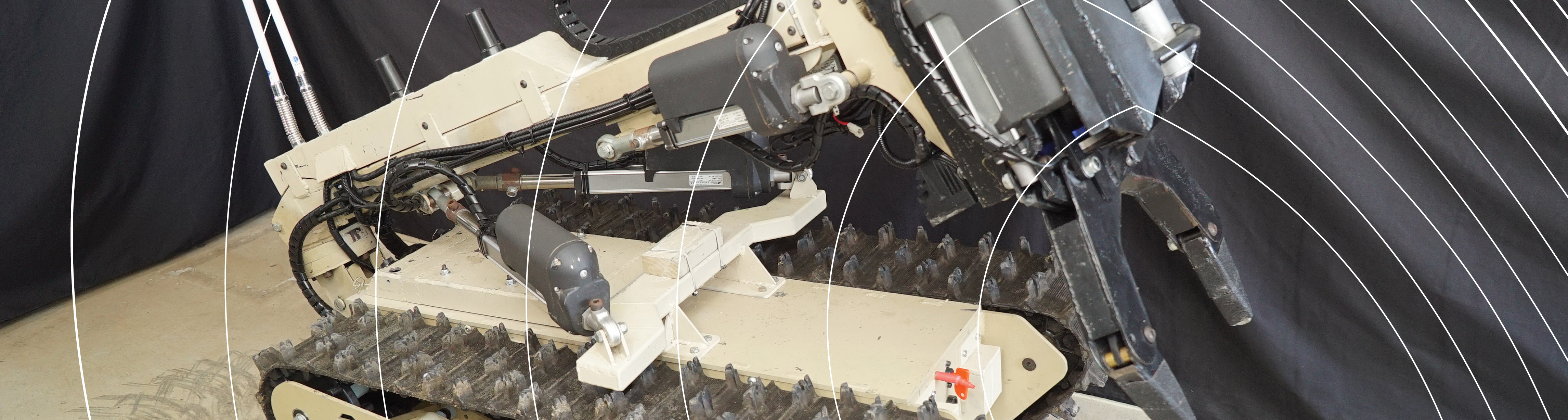

BIA5 Innovation Robotics and customers

BIA5 Pty Ltd is a start-up company that specialises in designing, manufacturing...

Harvey - the capsicum-picking robot

The horticulture industry in Australia has a gross value of more than $AU8...

Pegasus Alpha – Flying car

In the back streets of Brisbane, two brothers with a passion for the automotive industry had a feeling that the future is vertical.