CASE STUDY: IR4 – Mass communication via robotic automation

Case Studies

Since 2014, XM2 Aerial has been pioneering the use of unmanned aerial …

Go.Robot is an Australian company that distributes and configures robotic …

Laing O’Rourke – lifting frontline job satisfaction

Laing O’Rourke is a $AU6 billion international operation with 50 years of involvement …

Co-designing a robot for Indigenous Australian language revival

Opie the Robot is a technology deployed in classrooms in the southeast …

In the back streets of Brisbane, two brothers with a passion for the automative …

Share this story

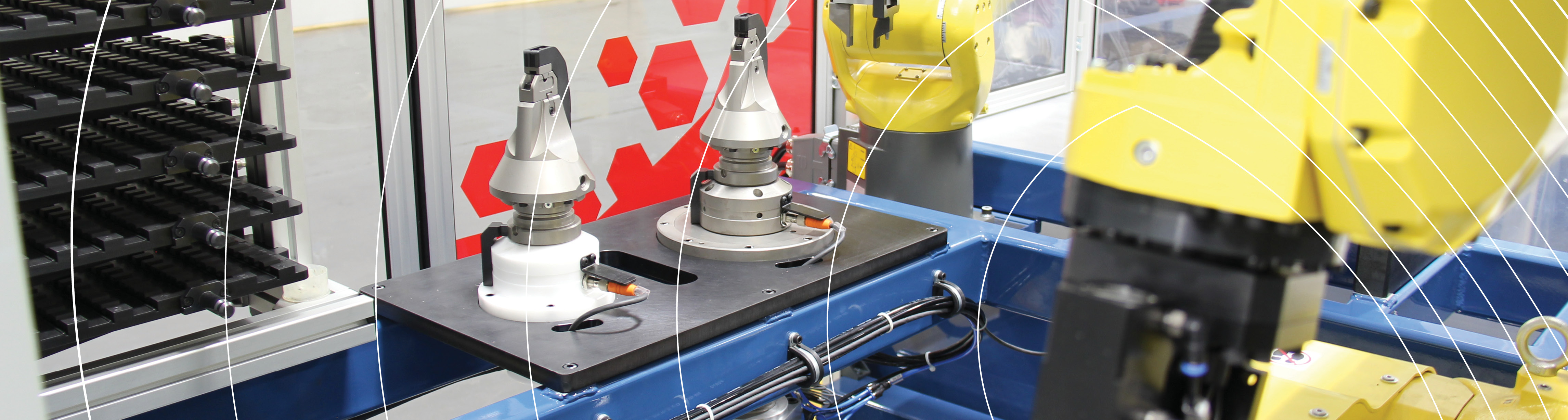

IR4 is an early revenue technology company that is setting global benchmarks in flexibility for the application of automation solutions.

By utilising 3D model data as the single key input to system automation and control, solutions become viable in manufacturing environments characterised by:

- low volume

- significant product and environmental variability

- large numbers of product variants.

Once a 3D model is imported, the system simply requires raw stock and consumables to be maintained to automatically manufacture the specified products. When the design / product changes, the system automatically reprograms itself with an upload of the revised 3D model.

IR4 licenses their technology to another Australian company, SSS Manufacturing, to fabricate structural steel. At SSS Manufacturing, the real-time automation solution uses the system’s artificial intelligence to calculate the most efficient way to process steel sections presented for fabrication. Processing includes all functions required to fabricate a steel section, being handling, blasting, scanning, cutting, coping, holing, welding, and painting. By using the 3D model, SSS Manufacturing has realised a reduction of more than 75 per cent in the labour content required to fabricate steel sections, despite incorporating innumerable variations, with 100% accuracy. This translates to significant customer benefits that include cost, quality, traceability, scheduling and ease of implementation of design changes.

IR4 is now working towards delivering extended capability and industry technology transfers. Additional capabilities being developed include:

- human machine collaboration

- solutions derived directly from 3D scanning data devoid of any 3D model data.

Trending Article

Working with robotics technology to improve safety, reliability and efficiency in high-risk and remote environments

Woodside is an Australian oil and gas company with a global presence, recognised for its world-class capabilities – as an explorer, a developer, a producer and a supplier of energy…

ANCA – Australia’s largest user of industrial robots

ANCA is an Australian company, founded in Melbourne in 1974, now with offices...

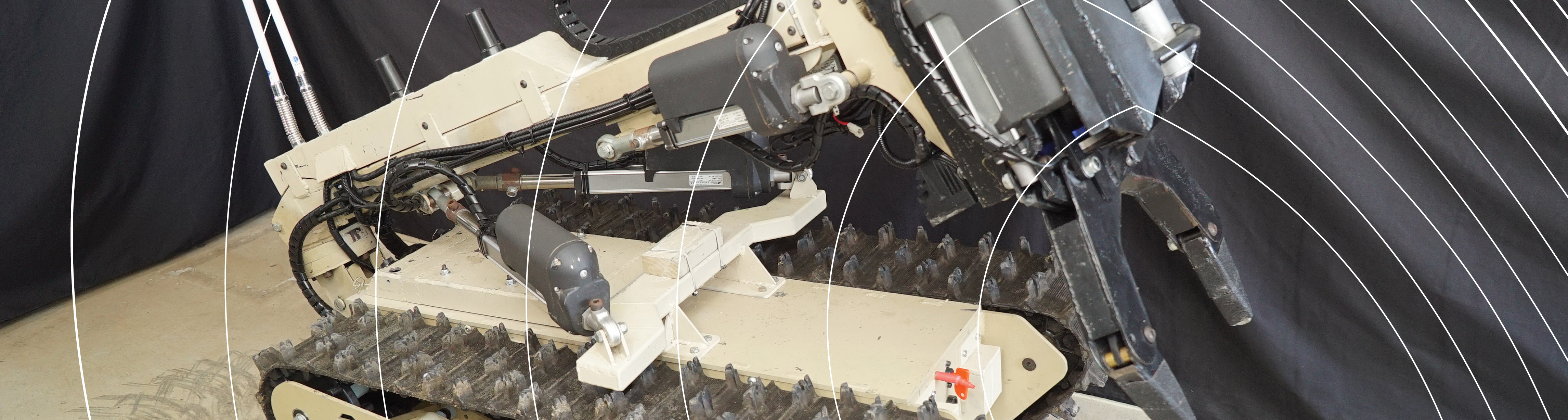

BIA5 Innovation Robotics and customers

BIA5 Pty Ltd is a start-up company that specialises in designing, manufacturing...

Harvey - the capsicum-picking robot

The horticulture industry in Australia has a gross value of more than $AU8...

Pegasus Alpha – Flying car

In the back streets of Brisbane, two brothers with a passion for the automotive industry had a feeling that the future is vertical.