CASE STUDY: Paddock to plate

Case Studies

Boeing Australia – Where humans and automation work together

Since the 2008 establishment of Boeing’s advanced research and development unit …

IR4 – Mass communication via robotic automation

IR4 is an early revenue technology company that is setting global benchmarks in …

Kalmar – AutoStrad Terminal Solution

Within the next 10-15 years many of the major stevedores will automate and the …

Wide area surveillance of the oceans requires a diversity of solutions …

Rio Tinto’s fleet of autonomous haul trucks have moved more than 1 billion tonnes of …

Share this story

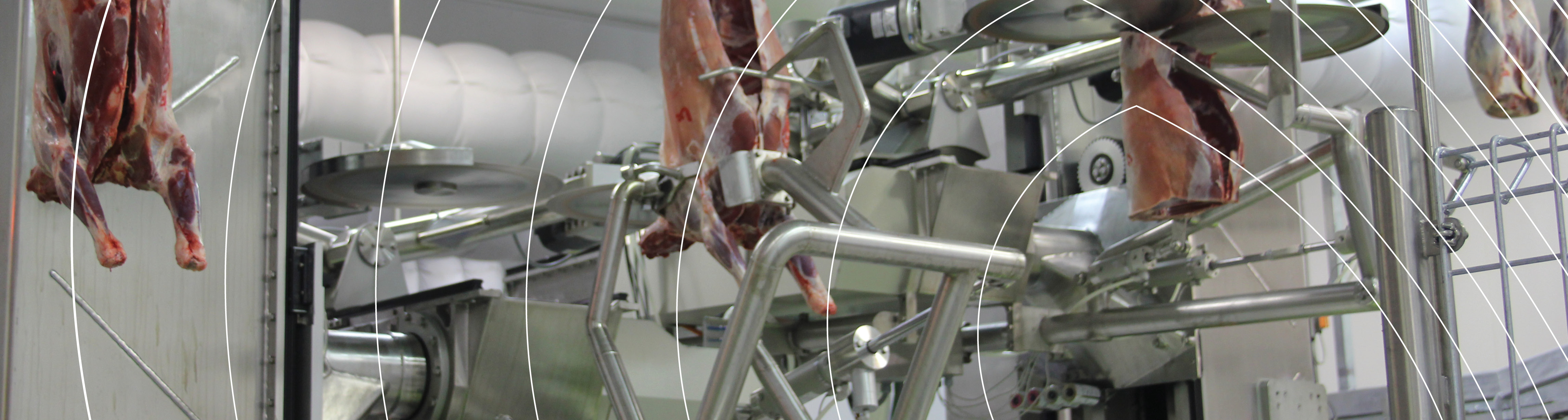

Meat & Livestock Australia (MLA) is currently driving an extensive $AU60 million program of advanced 2D and 3D imaging technologies, encompassing the full ‘paddock to plate’ red meat value chain. MLA has key strategic partnerships with leading domestic and global technology provider organisations, for example: hyperspectral imaging (US), dual energy xray (NZ), airline baggage CT (US), including both 2D and 3D modalities.

The imaging technologies are being developed for application: on-farm for livestock and pasture management with autonomous vehicles, in processing plants for livestock scanning for health diagnosis, in-plant for carcass robotic between-bone cutting lines, in-plant for robotic separation of meat from bones ‘robotic surgery’, and in-plant for robotic meat cut recognition with pick and packing into export cartons. Each has the objective of increasing value chain production and labour efficiencies.

MLA views the key opportunities of vision-assisted robotics as: the use of on-farm autonomous devices to conduct arduous or repetitive or time-consuming tasks, adding value to meat products through precise cutting and delivering high value-added products to selected markets, providing valuable process and product data to the value chain, and the ability to re-allocate valuable labour from arduous and repetitive processing tasks to value adding complex activities more suited to people.

Trending Article

An Australian university (ANU) has been the first to trial intelligent drones for automated inspection of solar power plants.

The project is an industry-researcher collaboration funded by the Australian government’s Australian Renewable Energy Agency (ARENA) developing a cost-effective robotic inspection system…

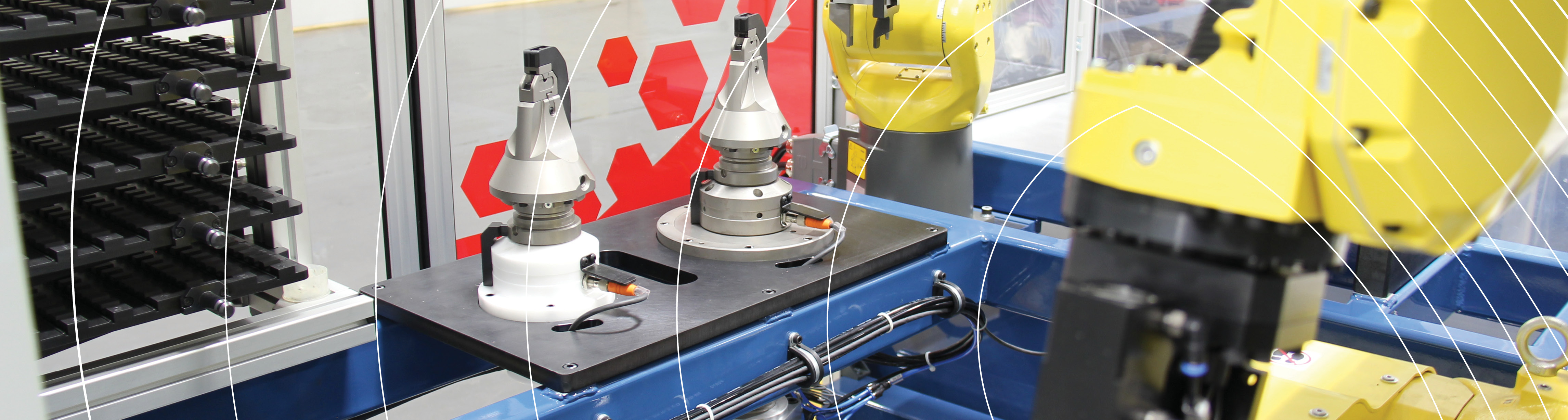

ANCA – Australia’s largest user of industrial robots

ANCA is an Australian company, founded in Melbourne in 1974, now with offices...

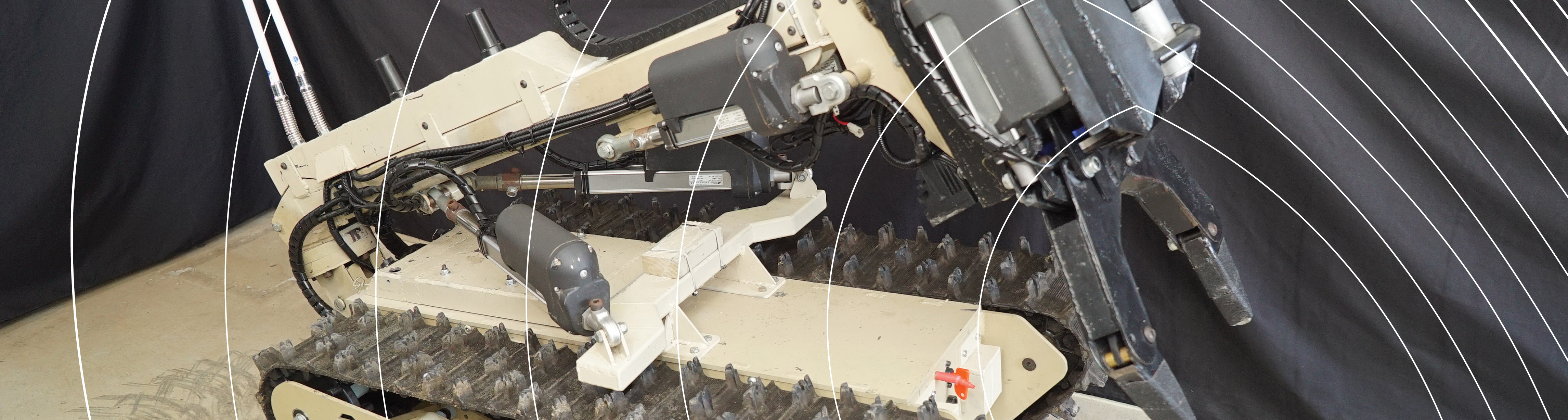

BIA5 Innovation Robotics and customers

BIA5 Pty Ltd is a start-up company that specialises in designing, manufacturing...

Harvey - the capsicum-picking robot

The horticulture industry in Australia has a gross value of more than $AU8...

Pegasus Alpha – Flying car

In the back streets of Brisbane, two brothers with a passion for the automotive industry had a feeling that the future is vertical.