The future of robotics in infrastructure

Despite the decline in resource-related construction, many major infrastructure projects have still been committed to, or, are under construction in areas where the resources sector dominates, such as northern Australia. According to Deloitte Access Economics data, northern Australia has 66 major projects worth around $AU201 billion being constructed or committed to, as at September 2016. These form around 46 per cent of all such projects across Australia and, due to their remote location, present unique challenges in transport of materials, supply of labour and communications [AIR16]. All are areas where robotic technologies can play a role.

There is also tremendous potential for application of these technologies in the inspection and maintenance of Australia’s extensive network of existing infrastructure [ACR14, IA15]. This infrastructure includes on/above ground structures, below ground structures, and underwater structures.

On/above ground structures

On and above ground structures such as buildings, roads, bridges, power/communication towers, wind turbine blades, solar power assets, and ports can be inspected cost-effectively using unmanned aerial vehicles (UAVs) and remotely operated aircraft systems [QDS17] with a suite of sensors, including cameras. These platforms are increasingly becoming robust, stable, and efficient, showing extended longevity with inherent larger payload handling capacities. Basic inspections using close-circuit television (CCTV) technology has been in the market for many years. Biologically inspired robots able to climb complex tower structures are being developed to carry out hectic and unsafe inspections. Robots operating in undesirable constrained environments, such as inspection of bridge arches and girders, are being developed and deployed. For example, complex inspection of Sydney Harbour Bridge (SHB) arches are now a reality using biologically inspired inchworm robots [SMH15, ABC16]. Autonomous grit-blasting robots, Sandy and Rosy, have been removing the paint of Sydney Harbour Bridge since 2013 [BBC13, UTS14]. Roads and railroads are expected to be inspected through highly efficient and accurate automated technologies for detecting defects, such as quality of lane markings, cracks and potholes, through multimodal data fusion methods [CSI16]. They are expected to be repaired by highly automated processes. Smart road conceptualises the built-in intelligence to the infrastructure by embedding cameras, automatic toll readers and other sensors to effectively manage traffic gridlocks, parking, on-demand and multimodal transport, response to incidents and other related issues while improving safety, efficiency and cost. The information made available to autonomous vehicles can improve the situation awareness, efficient journey planning, and advanced navigation capabilities in crowded urban roads. The Australian government is already trialling ‘vehicle-vehicle’ and ‘vehicle-infrastructure’ communication systems as part of the cooperative intelligent transport initiative [TIC16]. Sensing and vision systems are already heavily used in building information and inspection systems. Smart buildings with embedded sensors can efficiently control the building management systems to reduce waste while improving the quality of life. Building inspection systems with UAVs and climbing robots can reach the difficult to access areas with ease, avoiding occupational health and safety (OH&S) issues associated with human operators.

Belowground structures

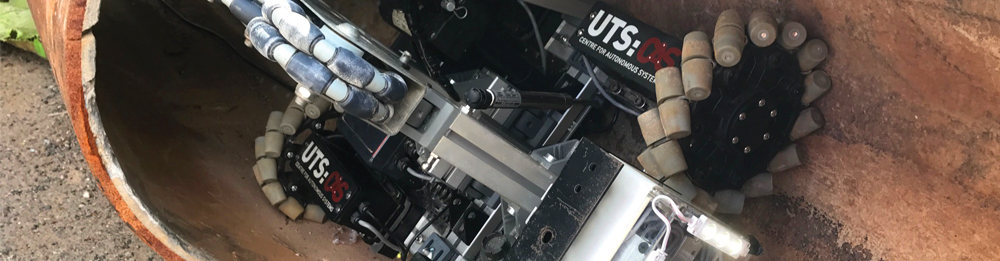

This includes many below ground infrastructures, such as oil/water/waste water pipes, large diameter tunnels, long-haul stretches, inverts, crowns, culverts, and manholes. Such infrastructures are difficult to access and may have other challenges such as the presence of debris, highly corrosive chemicals, and pressurised water/oil. The robotic platforms are increasingly capable of navigating such harsh environments over extended period of times, producing CCTV, 3D reconstructions, and defect profiling with ground penetrating radars, laser sensors and sonars. They can, to some extent, adapt to pipes with different sizes, shapes, and materials to accurately estimate the remaining ‘intact’ material for end-of-life estimations. Further, they are capable of preventative maintenance in terms of laying different types of liners and coatings. The sensing and robotic aspects of liners and coatings will be further investigated in the recently announced multinational 31-member partnership with Cooperative Research Centre project (CRC-P) on smart linings for pipes and infrastructure.

Underwater structures

A variety of robotic platforms are used for monitoring underwater structures, which include unmanned underwater vehicles (UUV), unmanned surface vehicles (USV), remotely operated vehicles (ROV) and submarines. They have cameras, acoustic, and other sensors for inspection of oil and gas pipes, ship hulls, underwater pylons, dams, and ocean beds. The robotics and vision systems are not only expected to carry out inspections, but they are frequently being used to undertake cleaning, paint/corrosion removal, repairing (welding) and deep-sea operations.

Non-technical challenges in infrastructure

Over the next decade, intelligent robotic technologies will have a significant impact on transforming smart infrastructure, inspection and maintenance. These transformations are likely to present abundant challenges; technical as well as non-technical. The key robotic technological advances required by Australian industry are outlined in Chapter 11, along with the key technical challenges facing Australia’s infrastructure over the next 15+ years. Non-technical challenges include:

- high cost of development, market penetration and certification

- acceptance of the technology by the workforce due to fear of losing jobs

- public acceptance of the technology

- acceptance of broad legislative and insurance frameworks

- data security and privacy issues

- requirement of early high-quality demonstration and completeness before adaptation.

Technical challenges in infrastructure

As identified in the Australian infrastructure plan [IA17], Australia has a large infrastructure maintenance backlog specifically in public owned/operated assets. There is a gap in the technology dealing with effective and efficient inspection and maintenance. Inspection needs robust sensing modalities, including vision and deployment strategies such as robotics. Maintenance requires sensing and robots as well as manipulation and actuation capability. The technologies need to be safe, efficient, robust, easy to use and of low cost to operate.

- Safer designs: Establishment of acceptable levels of safety, and safety certification, is needed for systems driven by advances in systems design methods that integrate safety into the design cycle, guaranteeing safety performance.

- Perception and control in complex operations: Significant improvements in perception, localisation and motion control systems (both in dynamic and unstructured 3D terrains, underwater and on the ground), and in terms of handling the effects of extreme conditions on perception and localisation.

- Locomotion: In complex structures such as towers, multi-shaped tunnels and pipes, bridges, chimney stacks, underwater structures and tall walls.

- Multi-robot co-operation: Command and control of teams of both heterogeneous and homogeneous robots including mixing robot teams with human teams working in close collaboration; scene interpretation and cognitive interpretation of both object and environment.