CASE STUDY: ANCA – Australia’s largest user of industrial robots

Case Studies

Boeing Australia – Where humans and automation work together

Since the 2008 establishment of Boeing’s advanced research and development unit …

IR4 – Mass communication via robotic automation

IR4 is an early revenue technology company that is setting global benchmarks in …

Kalmar – AutoStrad Terminal Solution

Within the next 10-15 years many of the major stevedores will automate and the …

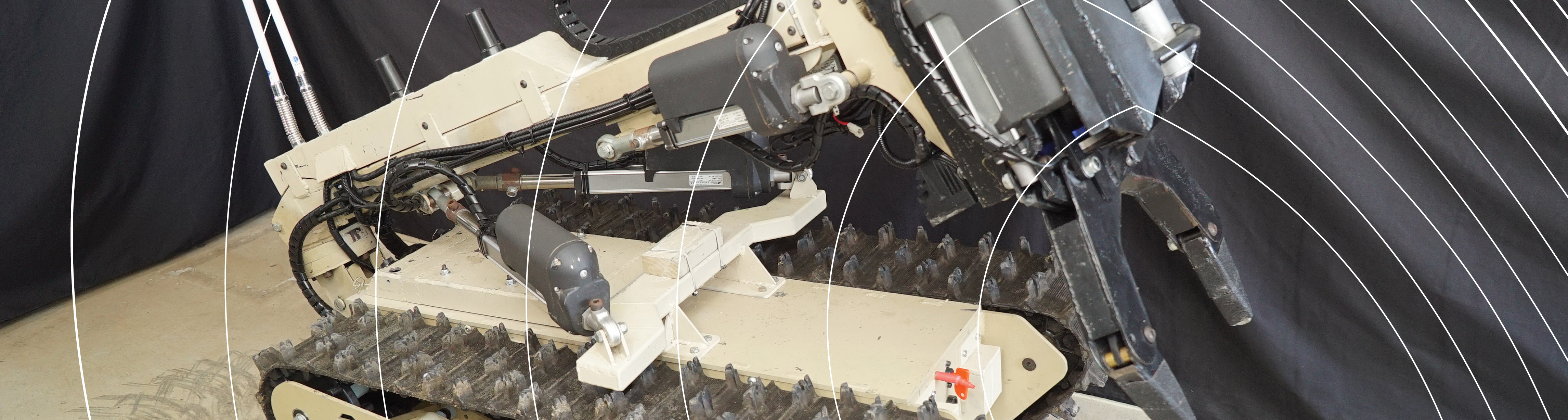

Wide area surveillance of the oceans requires a diversity of solutions …

Rio Tinto’s fleet of autonomous haul trucks have moved more than 1 billion tonnes of …

Share this story

ANCA is an Australian company, founded in Melbourne in 1974, now with offices around the globe. ANCA is the market leader of a high quality CNC (Computer Numerical Control) tool and cutter grinders supplying the aerospace, automotive, electronic, medical and other technologically advanced industries. The company has a sophisticated machine tool factory and employs highly skilled and specialised staff. Forming ANCA Motion in 2008, the company also produces CNC Control Systems, IO Devices, Servo drives and motors suitable for machine tool and motion control applications.

Until recently, machine tool users have not benefited greatly from robotics, with most applications dominated by manual tending. CNC grinders only have 1.5% of machine tools automated with robots. As robots become more affordable and easier to program, this trend is shifting.

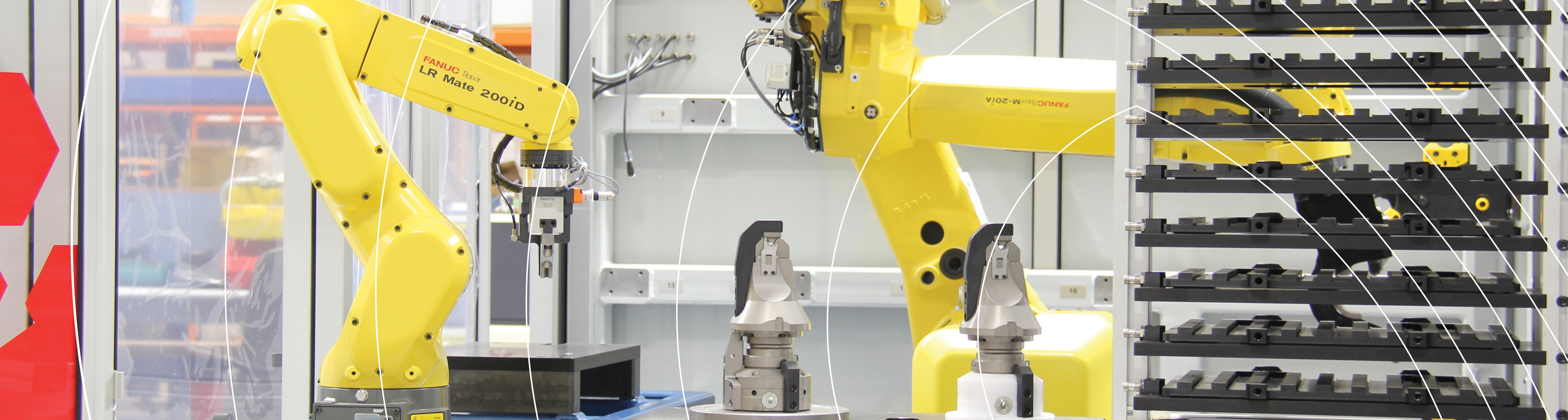

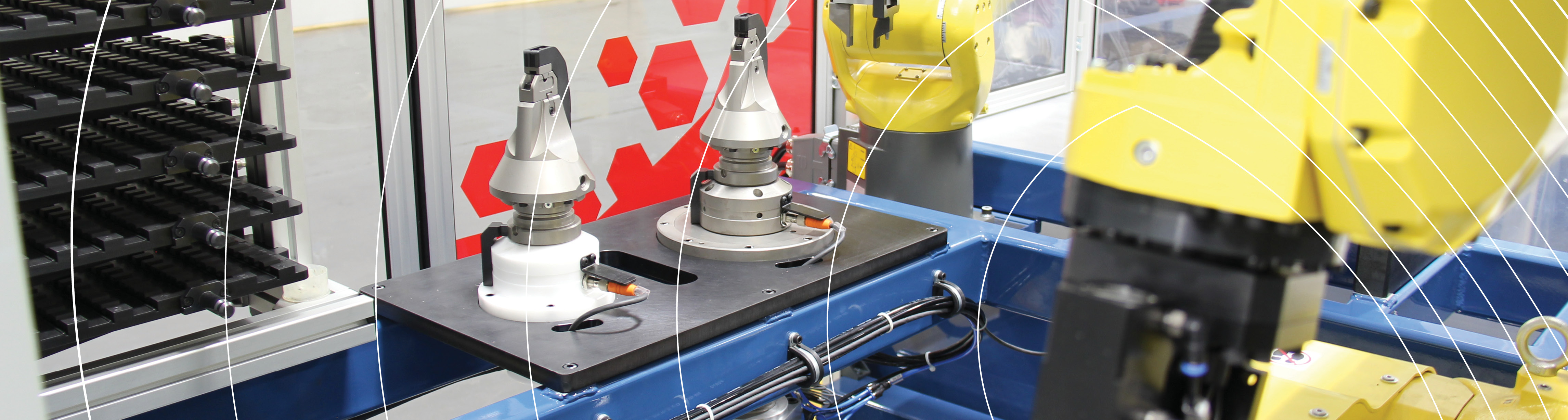

Since 2014, the number of ANCA customers ordering CNC Grinding Machines with robot loaders has increased from 10% to 50% of machines sold. In response to this demand, ANCA has developed an innovative new multi-robot production cell. It works by having a larger robot devoted to wheel pack changes and part loading. A second, smaller robot is then free to ‘multi-task’ other operations within the cell. This opens a whole range of machining possibilities as one CNC grinder can essentially become a flexible manufacturing cell. Customers have found the cell has a better capability to manage components that are difficult to hold, such as turbine blades and knee joints. The approach has the added benefit of allowing two processes to run simultaneously. For example, the large robot can load wheel packs and parts into the machine while the smaller robot completes operations such as metrology, laser etching, or part washing. The dual robot technology reduces capital equipment costs, improves productivity, and reduces work-in-progress and inventory.

ANCA’s world-first system is provided as a turnkey solution to several global customers. To build the dual robot technology, the company purchases between 35-40 robots per month but has plans to develop its own robotic manufacturing capability (see Case Study p. 18).

Trending Article

Working with robotics technology to improve safety, reliability and efficiency in high-risk and remote environments

Woodside is an Australian oil and gas company with a global presence, recognised for its world-class capabilities – as an explorer, a developer, a producer and a supplier of energy…

ANCA – Australia’s largest user of industrial robots

ANCA is an Australian company, founded in Melbourne in 1974, now with offices...

BIA5 Innovation Robotics and customers

BIA5 Pty Ltd is a start-up company that specialises in designing, manufacturing...

Harvey - the capsicum-picking robot

The horticulture industry in Australia has a gross value of more than $AU8...

Pegasus Alpha – Flying car

In the back streets of Brisbane, two brothers with a passion for the automotive industry had a feeling that the future is vertical.