CASE STUDY: Australia wins the Amazon Robotics Challenge

Case Studies

Boeing Australia – Where humans and automation work together

Since the 2008 establishment of Boeing’s advanced research and development unit …

IR4 – Mass communication via robotic automation

IR4 is an early revenue technology company that is setting global benchmarks in …

Kalmar – AutoStrad Terminal Solution

Within the next 10-15 years many of the major stevedores will automate and the …

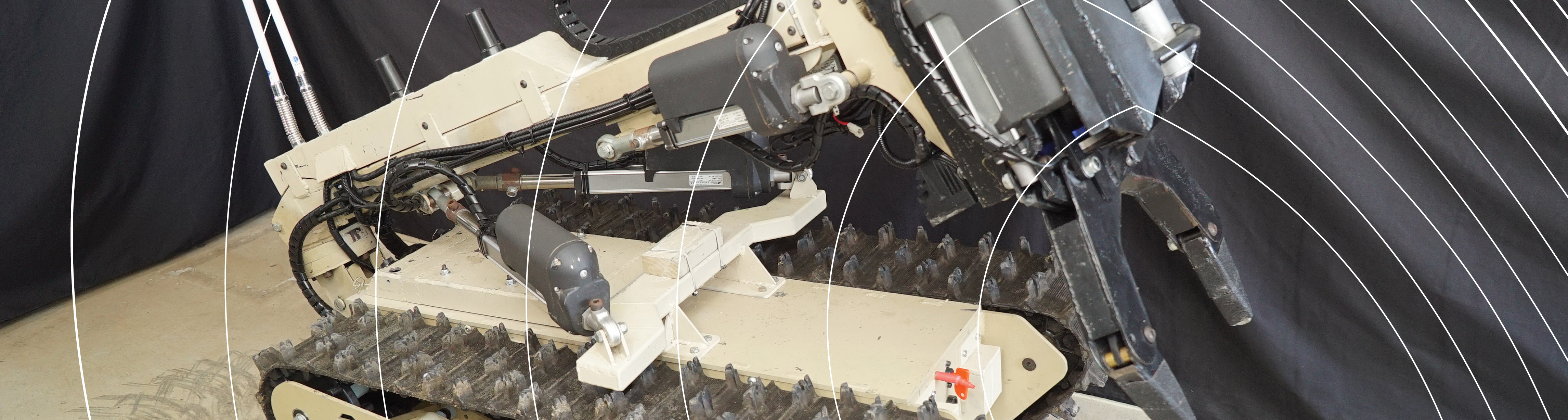

Wide area surveillance of the oceans requires a diversity of solutions …

Rio Tinto’s fleet of autonomous haul trucks have moved more than 1 billion tonnes of …

Share this story

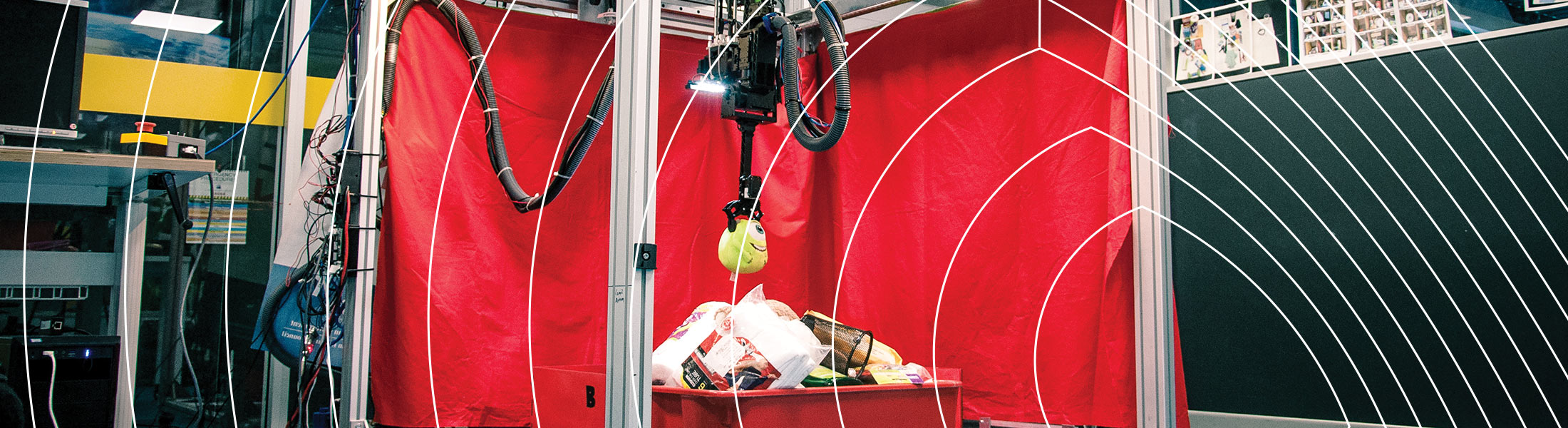

In 2017, a team from Australia won the Amazon Robotics Challenge to build an automated robot, including hardware and software, to successfully pick, and stow items in a warehouse. Amazon is one of the largest robotics companies in the world and requires the technology to quickly package and ship millions of items to customers from their global network of fulfilment centres. The commercial technologies to solve automated picking in unstructured environments are still being developed.

Using an in-house cartesian robot (Cartman) built for only $AU10,000, the team from the Australian Centre for Robotic Vision applied a novel few-shot learning algorithm to place first in the competition. The challenge combined object recognition, pose recognition, grasp planning, compliant manipulation, motion planning, task planning, task execution, error detection, and error recovery. The robots were scored by how many items they successfully picked, and stowed, in a fixed amount of time. They were also challenged by being given 16 unseen items just 45 minutes before the competition began.

Cartman can move along three axes at right angles to each other, like a gantry crane, and featured a rotating gripper that allowed the robot to pick up items using either suction or a simple two-finger grip. Cartman’s vision system was the result of hours of training data, and training time, but the team also had to create a robust vision system to cope with the unseen items. One feature of the vision system was that it worked off a very small amount of hand annotated training data. Cartman needed just seven images of each unseen item to be able to reliably detect them.

The robot was only unpacked and reassembled out of suitcases a few days before the event, and broke a wrist during the competition, which had to be quickly re-engineered and a replacement part 3D printed.

Trending Article

An Australian university (ANU) has been the first to trial intelligent drones for automated inspection of solar power plants.

The project is an industry-researcher collaboration funded by the Australian government’s Australian Renewable Energy Agency (ARENA) developing a cost-effective robotic inspection system…

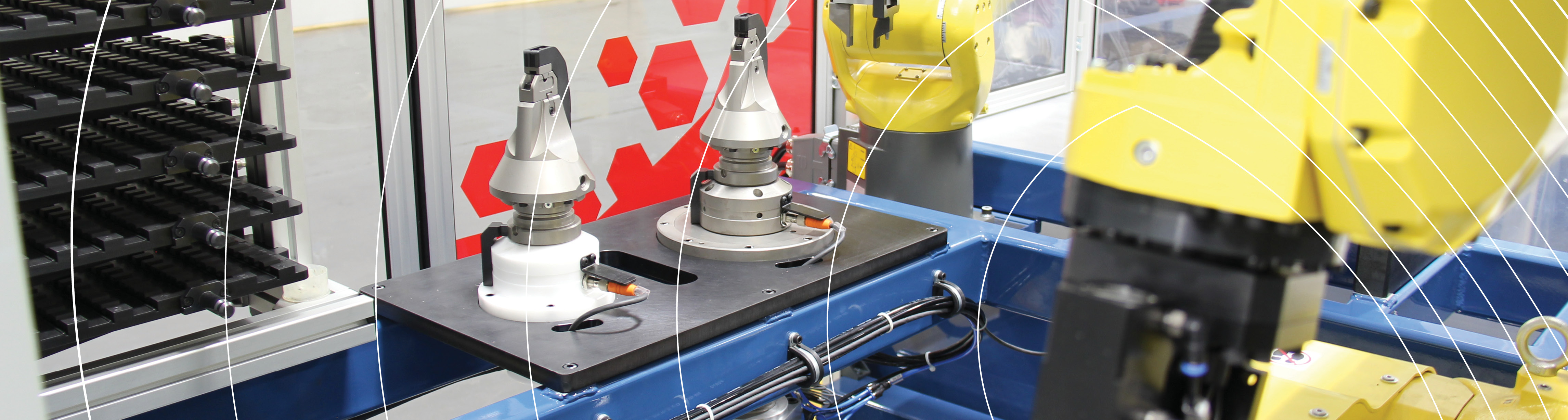

ANCA – Australia’s largest user of industrial robots

ANCA is an Australian company, founded in Melbourne in 1974, now with offices...

BIA5 Innovation Robotics and customers

BIA5 Pty Ltd is a start-up company that specialises in designing, manufacturing...

Harvey - the capsicum-picking robot

The horticulture industry in Australia has a gross value of more than $AU8...

Pegasus Alpha – Flying car

In the back streets of Brisbane, two brothers with a passion for the automotive industry had a feeling that the future is vertical.