CASE STUDY: Working with robotics technology to improve safety, reliability and efficiency in high-risk and remote environments

Case Studies

Boeing Australia – Where humans and automation work together

Since the 2008 establishment of Boeing’s advanced research and development unit …

IR4 – Mass communication via robotic automation

IR4 is an early revenue technology company that is setting global benchmarks in …

Kalmar – AutoStrad Terminal Solution

Within the next 10-15 years many of the major stevedores will automate and the …

Wide area surveillance of the oceans requires a diversity of solutions …

Rio Tinto’s fleet of autonomous haul trucks have moved more than 1 billion tonnes of …

Share this story

Woodside is an Australian oil and gas company with a global presence, recognised for its world-class capabilities – as an explorer, a developer, a producer and a supplier of energy.

Woodside seeks to enhance its competitiveness through innovation and applying technology that improves safety, reliability and efficient operations in the high-risk and remote environments where they operate.

In mid-2017, Woodside took delivery of one of NASA’s Anthropomorphic Robonauts, which is on loan for a five-year deployment in Perth, Western Australia. The NASA Robonaut project will explore how robotic technology can be used to unlock value from Woodside’s assets.

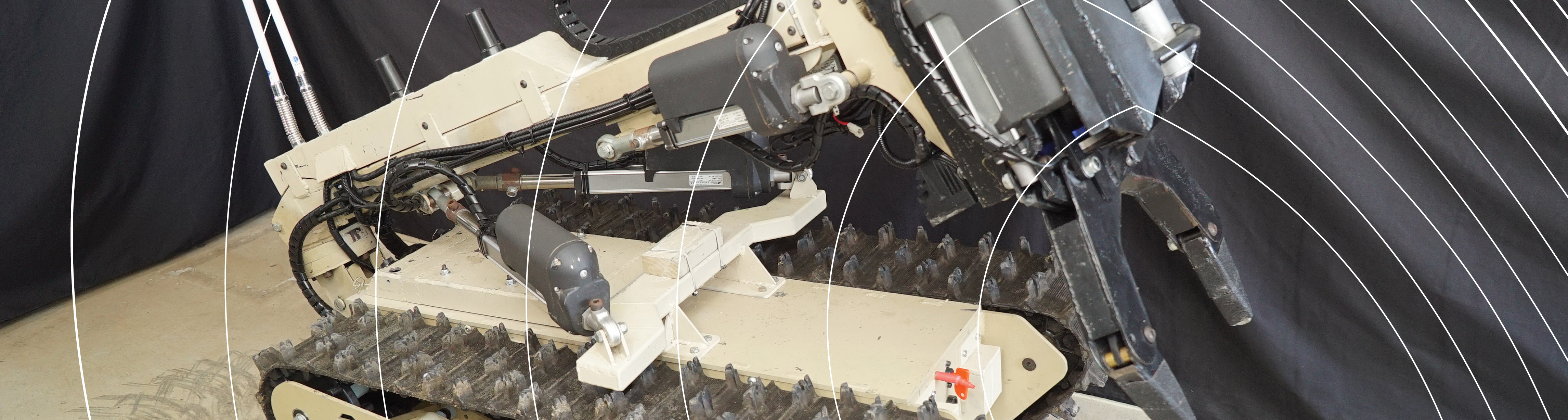

The Robonaut project complements Woodside’s own robotics program that includes machines capable of conducting tele-operated and semi-autonomous patrols and inspections that were suggested by their operational staff. The first site trial of Woodside’s patrol and inspection machines took place in November 2017 at the Pluto LNG facility. In addition to performing repetitive or high-risk tasks, the robots are also acting as mobile sensor platforms – streaming visual, thermal, ultrasonic, and light detection and ranging (LIDAR) data into Woodside’s existing cognitive and analytics programs. The data gathered is processed and sent to operations and maintenance teams to assist them in identifying equipment faults, errors or where capacity improvements exist.

Further trials are planned at Woodside’s onshore and offshore facilities throughout 2018.

Trending Article

Working with robotics technology to improve safety, reliability and efficiency in high-risk and remote environments

Woodside is an Australian oil and gas company with a global presence, recognised for its world-class capabilities – as an explorer, a developer, a producer and a supplier of energy…

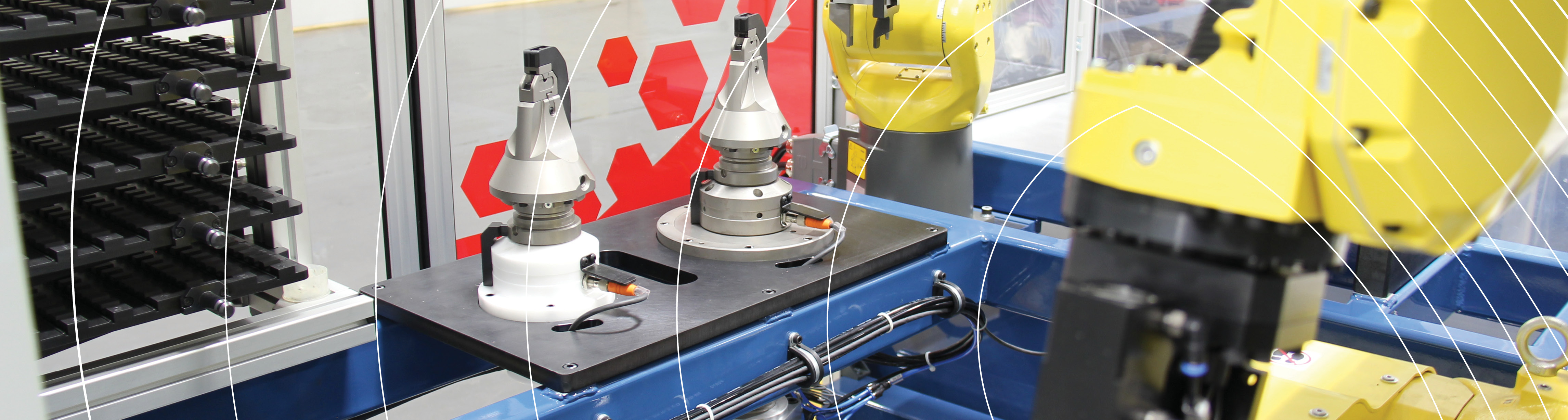

ANCA – Australia’s largest user of industrial robots

ANCA is an Australian company, founded in Melbourne in 1974, now with offices...

BIA5 Innovation Robotics and customers

BIA5 Pty Ltd is a start-up company that specialises in designing, manufacturing...

Harvey - the capsicum-picking robot

The horticulture industry in Australia has a gross value of more than $AU8...

Pegasus Alpha – Flying car

In the back streets of Brisbane, two brothers with a passion for the automotive industry had a feeling that the future is vertical.