CASE STUDY: Fastbrick bricklaying robot company listed on Australian stock exchange

Case Studies

Boeing Australia – Where humans and automation work together

Since the 2008 establishment of Boeing’s advanced research and development unit …

IR4 – Mass communication via robotic automation

IR4 is an early revenue technology company that is setting global benchmarks in …

Kalmar – AutoStrad Terminal Solution

Within the next 10-15 years many of the major stevedores will automate and the …

Wide area surveillance of the oceans requires a diversity of solutions …

Rio Tinto’s fleet of autonomous haul trucks have moved more than 1 billion tonnes of …

Share this story

Fastbrick Robotics is a start-up company that is revolutionising the brick laying industry by using mobile robotic technology. The system uses a pre-existing plan of the building and environment, and with laser guidance (a mature technology), it is able to accurately and quickly lay out the bricks [AAS18].

Fastbrick Robotics have developed a truck mounted robot that works in conjunction with their proprietary building design software and has the capability to lay the bricks for a render ready, standard home in approximately 15 hours (around 1,000 bricks per hour).

The truck is fitted with a brick handling system which will cut and rout the bricks as required then send them along a 25-metre boom to a specially designed lay head. The lay head will apply a dedicated adhesive and lay the bricks to within 0.5mm of design specification under a laser guidance system, which manages any dynamic interferences (vibration, wind etc).

The safety of this system has been carefully designed and analysed to comply with the requirements of Australian Workplace Health and Safety legislation (minimising risk by design) and relevant standards (e.g., AS 4024.1-2014 Safety of Machinery and AS 62061 Functional safety of safety-related electrical, electronic and programmable electronic control systems).

Although fully automated while in operation, the machine is designed to be managed by trained operators. Safety of humans is fully assured by the system design.

Fastbrick Robotics has received worldwide attention for this highly innovative robotic system and have recently signed Memorandum of Understanding (MOUs) with Caterpillar and the Kingdom of Saudi Arabia, highlighting the global interest in this unique Australian robot. The KSA MOU is for the construction of 50,000 homes by 2022 and is estimated to require at least 100 bricklaying robots.

Trending Article

Working with robotics technology to improve safety, reliability and efficiency in high-risk and remote environments

Woodside is an Australian oil and gas company with a global presence, recognised for its world-class capabilities – as an explorer, a developer, a producer and a supplier of energy…

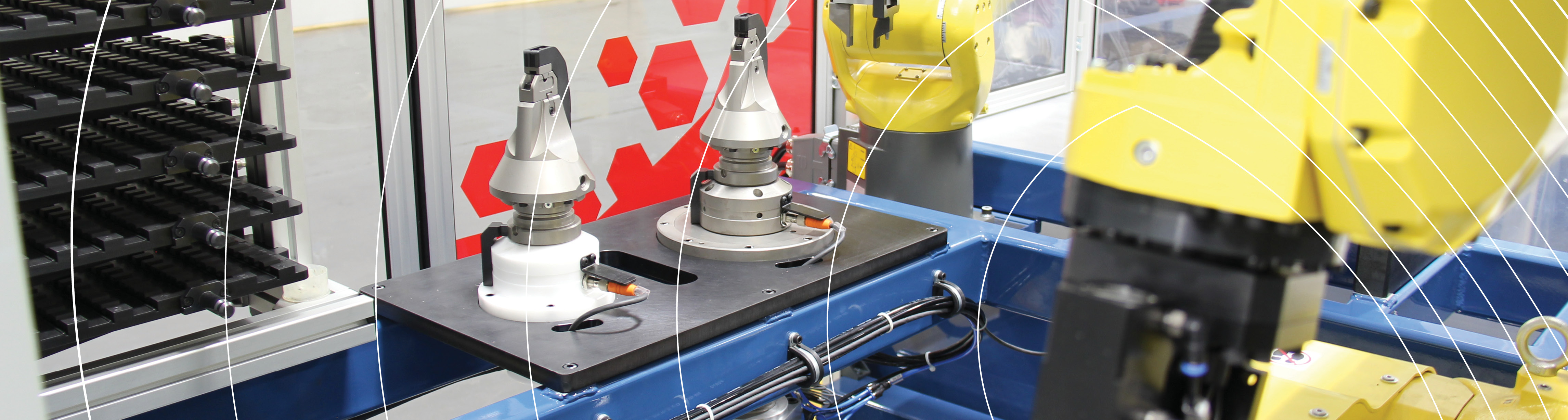

ANCA – Australia’s largest user of industrial robots

ANCA is an Australian company, founded in Melbourne in 1974, now with offices...

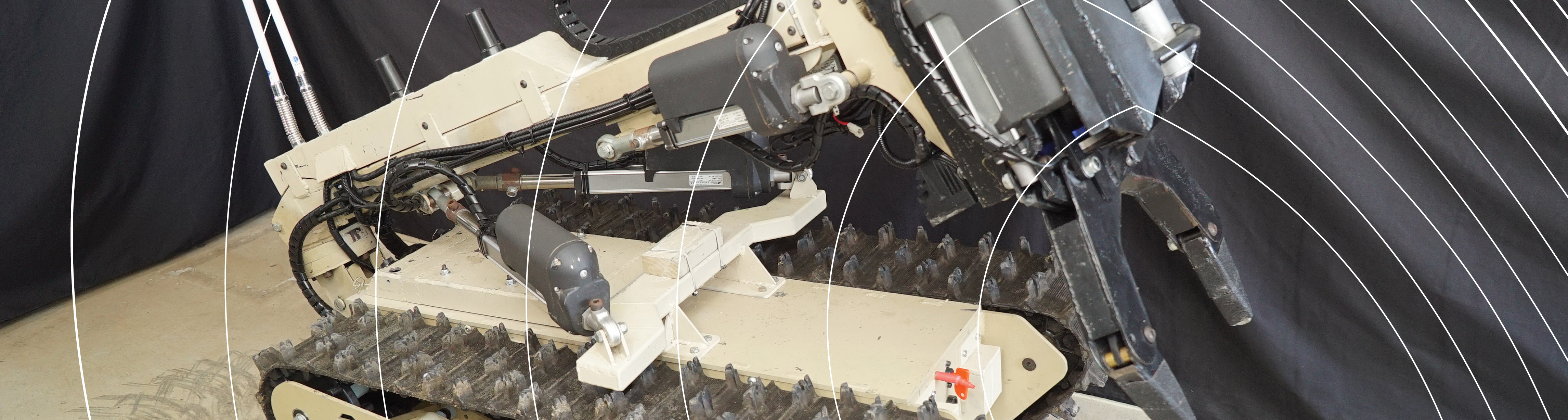

BIA5 Innovation Robotics and customers

BIA5 Pty Ltd is a start-up company that specialises in designing, manufacturing...

Harvey - the capsicum-picking robot

The horticulture industry in Australia has a gross value of more than $AU8...

Pegasus Alpha – Flying car

In the back streets of Brisbane, two brothers with a passion for the automotive industry had a feeling that the future is vertical.