CASE STUDY: ROAMES

Case Studies

Boeing Australia – Where humans and automation work together

Since the 2008 establishment of Boeing’s advanced research and development unit …

IR4 – Mass communication via robotic automation

IR4 is an early revenue technology company that is setting global benchmarks in …

Kalmar – AutoStrad Terminal Solution

Within the next 10-15 years many of the major stevedores will automate and the …

Wide area surveillance of the oceans requires a diversity of solutions …

Rio Tinto’s fleet of autonomous haul trucks have moved more than 1 billion tonnes of …

Share this story

The Queensland University of Technology (QUT), Cooperative Research Centre Spatial Information (CRCSI), and Ergon Energy’s Flight Assist System (FAS) technology reduces pilot workload, enhances pilot safety, and enables rapid data capture to help improve the task of state-wide power line network inspection.

The costs of managing a large power line network are significant, including high physical demands on, and personal risk to, workers. Queensland’s Ergon Energy’s network includes over 150,000 kilometres of power lines, 100 million trees, and 600 towns and cities.

Traditionally, the vital task of inspecting vegetation encroachment on powerlines was performed by time-consuming and expensive ground crew inspection. The alternative of using inspection aircraft requires flying for long periods of time at low altitude above power lines, which is potentially unsafe and tedious for pilots. To overcome these issues, QUT, CRCSI, and Ergon developed the FAS aircraft autonomy technology. This includes optimised flight planning, in-flight quality assurance, and resilient flight control technology that plans and then executes semi-autonomous flight over power line infrastructure at low altitudes to capture high-quality sensor data. The aerially-collected data is the key enabler for the Remote Observation Automated Modelling Economic Simulation (ROAMES) system. ROAMES has enabled a substantial reduction in the maintenance costs of Ergon Energy’s power line network (by $AU40 million per year) and has changed the way large-scale power infrastructure is managed. For example, in February 2015, Category 5 cyclone Marcia destroyed 350 homes. ROAMES enabled rapid prioritisation of recovery activities and Ergon Energy restored power to more than 51,000 customers (80 per cent of those impacted) within a record 10 days, saving more than $AU10 million. In 2015, the ROAMES system was awarded an International Edison Award for Innovation and a Queensland Spatial Excellence Award.

Trending Article

Working with robotics technology to improve safety, reliability and efficiency in high-risk and remote environments

Woodside is an Australian oil and gas company with a global presence, recognised for its world-class capabilities – as an explorer, a developer, a producer and a supplier of energy…

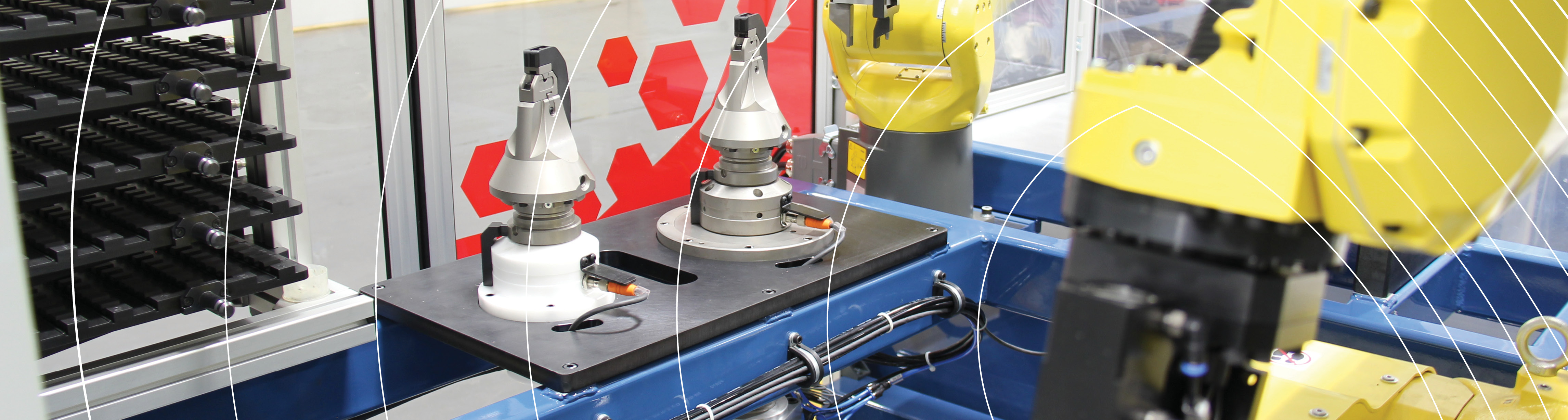

ANCA – Australia’s largest user of industrial robots

ANCA is an Australian company, founded in Melbourne in 1974, now with offices...

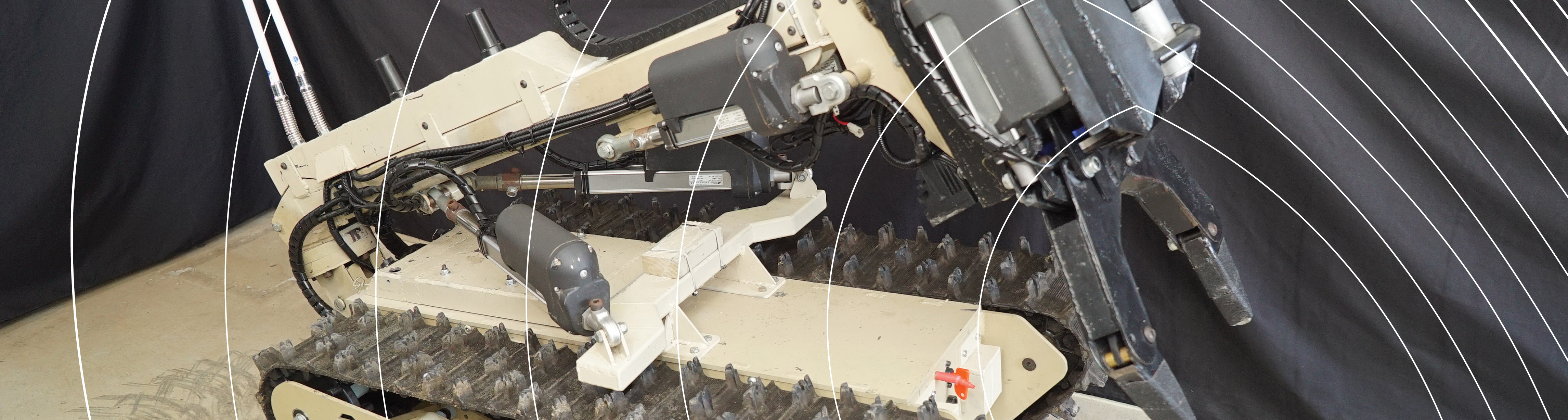

BIA5 Innovation Robotics and customers

BIA5 Pty Ltd is a start-up company that specialises in designing, manufacturing...

Harvey - the capsicum-picking robot

The horticulture industry in Australia has a gross value of more than $AU8...

Pegasus Alpha – Flying car

In the back streets of Brisbane, two brothers with a passion for the automotive industry had a feeling that the future is vertical.